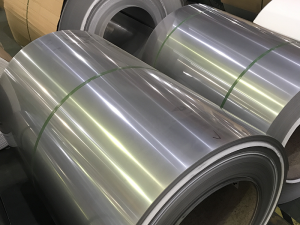

Coil Dur Di-staen 410S

Disgrifiad

Manylebau:

1.Standard: ASTM A240, JIS G4304, EN10088

2. Gradd: 200series&300series&400series

3. Trwch: 0.03mm - 6.0mm

4. Lled: 8mm-600mm

5. Hyd: fel cais cwsmeriaid

6. Arwyneb: 2D, 2B, BA, Drych gorffenedig, N04, Llinell Gwallt, gorffeniad Matt, 6K, 8K

7.Technology: tynnu oer / rholio oer / rholio poeth

Deunyddiau:

| Math | Gradd | Gradd | Cydran Cemegol % | ||||||||||

| C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | Arall | |||

| Austenitig | 201 | SUS201 | ≤0.15 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | ≤0.060 | ≤0.030 | - | ≤1.00 | - | ≤0.25 | - |

| 202 | SUS202 | ≤0.15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | ≤0.060 | ≤0.030 | ≤1.00 | - | ≤0.25 | - | ||

| 301 | 1. 4310 | ≤0.15 | 16.00-18.00 | 6.00-8.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | ≤0.10 | - | |

| 304 | 1. 4301 | ≤0.07 | 17.00-19.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 304L | 1. 4307 | ≤0.030 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 304H | 1.4948 | 0.04-0.10 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 309 | 1.4828 | ≤0.20 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 309S | * | ≤0.08 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 310 | 1.4842 | ≤0.25 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - | |

| 310S | * | ≤0.08 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.50 | - | - | - | |

| 314 | 1.4841 | ≤0.25 | 23.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | 1.50-3.00 | - | - | - | |

| 316 | 1. 4401 | ≤0.08 | 16.00-18.50 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316L | 1. 4404 | ≤0.030 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316Ti | 1.4571 | ≤0.08 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0.045 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | 0.1 | Ti5(C+N)~0.70 | |

| 317 | * | ≤0.08 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 317L | 1.4438 | ≤0.03 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0.045 | ≤0.030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 321 | 1.4541 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 321H | * | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Ti5(C+N)~0.70 | |

| 347 | 1. 4550 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10*C%-1.10 | |

| 347H | 1.494 | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0.045 | ≤0.030 | - | ≤1.00 | - | - | Nb≥10*C%-1.10 | |

| Deublyg | 2205 | S32205 | ≤0.03 | 22.0-23.0 | 4.5-6.5 | ≤2.00 | ≤0.030 | ≤0.020 | 3.0-3.5 | ≤1.00 | - | 0.14-0.20 | |

| 2507 | S32750 | ≤0.03 | 24.0-26.0 | 6.0-8.0 | ≤1.20 | ≤0.035 | ≤0.020 | 3.0-5.0 | ≤0.80 | 0.5 | 0.24-0.32 | ||

| Fferit | 409 | S40900 | ≤0.03 | 10.50-11.70 | 0.5 | ≤1.00 | ≤0.040 | ≤0.020 | - | ≤1.00 | - | ≤0.030 | Ti6(C+N)~0.50 Nb:0.17 |

| 430 | 1Cr17 | ≤0.12 | 16.00-18.00 | - | ≤1.0 | ≤0.040 | ≤0.030 | - | ≤1.0 | - | - | - | |

| 444 | S44400 | ≤0.025 | 17.50-19.50 | 1 | ≤1.00 | ≤0.040 | ≤0.030 | 1.75-2.5 | ≤1.00 | - | 0.035 | Ti+Nb:0.2+4(C+N)~0.80 | |

| Martensite | 410 | 1Cr13 | 0.08-0.15 | 11.50-13.50 | 0.75 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - |

| 410S | * | ≤0.080 | 11.50-13.50 | 0.6 | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 420 | 2Cr13 | ≥0.15 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| 420J2 | 3Cr13 | 0.26-0.35 | 12.00-14.00 | - | ≤1.00 | ≤0.040 | ≤0.030 | - | ≤1.00 | - | - | - | |

| PH | 630 | 17-4PH | ≤0.07 | 15.00-17.50 | 3.00-5.00 | ≤1.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | 3.00-5.00 | - | Nb 0.15-0.45 |

| 631 | 17-7PH | ≤0.09 | 16.00-18.00 | 6.50-7.50 | ≤1.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | ≤0.50 | - | Al 0.75-1.50 | |

| 632 | 15-5PH | ≤0.09 | 14.00-16.00 | 3.50-5.50 | ≤1.00 | ≤0.040 | ≤0.030 | 2.00-3.00 | ≤1.00 | 2.5-4.5 | - | Al 0.75-1.50 | |

Gwybodaeth Sylfaenol

Coil Dur Di-staen 410s, gydag ymwrthedd cyrydiad da a pheiriant, mae'n ddur pwrpas cyffredinol a dur offer torri.Mae 410S yn fath o ddur a all wella ymwrthedd cyrydiad a ffurfadwyedd 410 o ddur. Mae 410S yn ddur cryfder uchel a all wella ymwrthedd cyrydiad 410 o ddur ymhellach.Fe'i defnyddir ar gyfer llafnau tyrbin a rhannau tymheredd uchel.

• Manylebau: AISI 410s, ASTM 410s

• Gorffeniadau: Mae gan arwyneb Ba, arwyneb 2b, Rhif 1 (croen gwyn), arwyneb 2D, Rhif 4 (barugog), HL (lluniad gwifren), arwyneb 8K ansawdd arwyneb rhagorol

•Goddefiannau melin ar drwch a gwastadrwydd yn berthnasol. Ffoniwch JM Steel os oes angen meintiau penodol neu gyfeiriad grawn arnoch.

410S Technoleg peiriannu nodweddiadol

1D - Mae gan yr wyneb siâp gronynnog amharhaol, a elwir hefyd yn arwyneb niwl.

Technoleg prosesu: rholio poeth + ergyd anelio peening piclo + rholio oer + piclo anelio.

2D - Lliw gwyn ychydig yn ariannaidd.

Technoleg prosesu: rholio poeth + ergyd anelio peening piclo + rholio oer + piclo anelio.

2B - Arian gwyn gyda gwell sglein a gwastadrwydd nag arwyneb 2D.

Technoleg prosesu: rholio poeth + ergyd anelio peening piclo + rholio oer + piclo anelio + diffodd a thymheru rholio.

Ba - Sglein arwyneb ardderchog, adlewyrchedd uchel, fel wyneb drych.

Technoleg prosesu: rholio poeth + ergyd anelio peening piclo + rholio oer + piclo anelio + caboli wyneb + diffodd a rholio tymheru.

Rhif 3 -- Sglein da, arwyneb grawn bras.

Technoleg prosesu: caboli a thymeru rholio ar gyfer 2D neu 2B gyda 100 ~ 120 o ddeunyddiau sgraffiniol (JIS R6002).

Rhif 4 -- Sglein da, llinellau mân ar yr wyneb.

Proses brosesu: caboli a thymeru rholio ar gyfer 2D neu 2B gyda 150 ~ 180 o ddeunyddiau sgraffiniol (JIS R6002).

HL - Llwyd arian gyda rhediadau gwallt.

Technoleg prosesu: Mae cynhyrchion 2D neu gynhyrchion 2B gyda gronynnedd priodol o ddeunyddiau sgraffiniol ar gyfer caboli'r wyneb yn grawn sgraffiniol parhaus.

MIRRO -- Specular.

Technoleg prosesu: cynhyrchion 2D neu gynhyrchion 2B gyda gronynnedd priodol y deunydd malu malu a sgleinio i'r effaith drych.